Due to the high demand of a high quality acrylic display in retail, corporate and exhibit settings, there is no greater need to get the appearance of glass-like finishes than ever. The realization of optical clarity and professional edge finish on the acrylic pieces has been a long term challenge to the fabricators, more so to the industries that have the acrylic pieces on display with all their edges polished. Introducing oxy hydrogen generator water welder technology- new technology that has transformed the industry of flame polishing acrylic.

Conventional manual and abrasive techniques of polishing, though repairable with low-end finishing, fail to provide the transparency needed in high-end finishes of luxury retail stores, museum displays, and in architectural finishes. The acrylic display fabricators have therefore adopted hydrogen oxygen acrylic flame polishing which is capable of producing smooth edges that can not be beaten and optical clarity at high speed. We have discussed in this blog the ways how to flame polish acrylic in which the use of advanced flame polishers for acrylic technology is establishing a new standard in the industry in terms of acrylic flame polishing equipment selection as well as process mastery and the trend of the future.

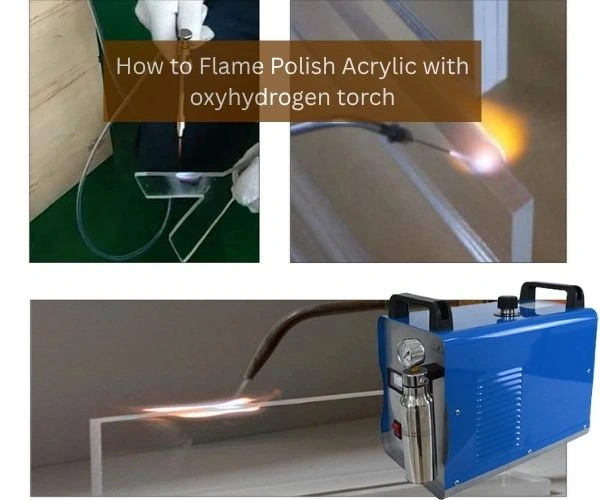

Central to this change is the oxy hydrogen generator water welder– which is an electrolytic machine that separates the distilled water into H2 and O2 to generate HHO gas when it needs it. This is a carbon free, flammable HHO gas that drives the oxygen-hydrogen generator water welder torch, which has flame temperatures up to 2800o C. This amount of heat is necessary in order to melt and smooth acrylic edges instantly.

The HHO torch produces a zero-carbon clean flame unlike acetylene or propane-based flames, there are no sooty residues or discoloration after it has been used to cut. Oxy hydrogen systems are seen as much safer as well: the gas is produced when it is needed and thus there is no reason for leaks or explosions of gas cylinders on high pressure that are commonly observed with the traditional polishing techniques.

Pre-Polishing Preparation

The first step to flame polishing acrylic edges clarity is cutting and machining. There should be no deep gouges or chipping on the surfaces and they are to be prepared to a finish of fine sanded of up to 600 grit. Prior to flame polishing, operators check the consistency and make sure that the acrylic sheet is clean and dry. The most important thing is safety- persons should wear proper personal protective gear when using the acrylic flame polishing torch.

Machine Setup and Calibration

The acrylic flame polishing torch machine can be installed correctly by making potassium hydroxide or sodium hydroxide electrolyte,and then turning the voltage (220/110 V) on. The third step is to inspect all the connections. Depending on the acrylic thickness, the intensity and shape of the flame are to be adjusted to the maximum and one must take care not to burn or bend down the flame.

The Polishing Technique

The process of flame polishing acrylic requires the use of a torch and holding it 2-5 cm to the edge and sweeping the length of the edge at a steady speed. Micro-flame polishing gives the freedom to do work on lines and tiny components and the temperature is controlled by avoiding overheating. Thick areas can be subjected to multiple passes, with a pause between treatment always being possible.

Model TX-HO100 Professional Specifications

It is a bench-top acrylic flame polishing machine that operates on typical AC voltages (220/110 V) and generates up to 100L/h of HHO gas at a peak pressure of 0.1-0.14Mpa. It takes up the space of a small shop with its tiny dimensions of 520x300x540mm and weighs only 15kg which is portable.

Advanced oxy Hydrogen Generator Water Welder Machine Features

In acrylic manufacturing on industrial scale, machines with a 200-600L/h production, flange-shaped electrolytic cell, and dual welding/polishing options simplify the operating and maintenance processes as well as high-volume production. The alkaline electrolysis in these units helps in lowering the costs of operation and this offers scalable solutions to the global manufacturers.

Superior Finish Quality

Flame polishing of acrylic edge clarity results in polished acrylic edge refinement that cannot be distinguished by optical glass and removes visible scratches and seams. The intricate forms and details are always left to become smooth and high-gloss as well as professional.

Environmental Benefits

The carbon emission polishing is done to zero carbon emission polishing to provide a cleaner working environment. A little waste is experienced as water and electricity are the only resources that are used, no chemicals or abrasive materials.

Economic Advantages

The acrylic finishing methods flame polisher is much cheaper in terms of operations compared to the gas systems based on cylinders. No repeat cylinders rental or refills and flame polishing acrylic can be less labor intensive which saves time in production.

Retail Display Applications

Luxury retail, jewelry and museum acrylic shows require edge sharpness and uniformity. Flame polishing is used so that the products such as point of sale stands and protective cases are of maximum visual quality.

Commercial and Industrial Uses

Durable, flame-polished acrylic is beneficial to corporate offices, electronic housings and interior design features in terms of functionality and aesthetics.

Specialized Manufacturing

Tight tolerances and biocompatibility With the acrylic fabrication polishing process and special flame polishing method, it is easy to achieve tight tolerances and biocompatibility with high-end consumer products as with medical devices as well as optical sensors.

High-grade cast acrylic is the only type that can be selected. Special flame calibration may be needed with very thick or colored acrylics.

Surface roughness measurements and inspections will be done visually to ensure consistency in clarity. Bubbles, streaks or dullness are some of the defects that are detected and rectified before delivery.

The risks associated with the high temperature and open flame during flame polishing acrylic process need to be mitigated by the use of proper training, good ventilation and PPE.

Initial Investment Considerations

A flame polisher for acrylic made by a professional can cost more at first than a simple abrasive system, but less in consumables and less in manual labor will be saved in the long run.

Operating Cost Analysis

Maintenance is low, being water and electricity costs basically all the time and only a periodic electrode check and a periodic change of water. The production cycles are quickened and this increases the output and efficiently used labor force.

Quality Premium Benefits

Glass-like finishing also allows the acrylic fabricators to charge higher prices, retain more customers and always win over those who use the traditional mechanical polishing.

CNC-controlled flame polishing, robotic arms and IoT-based maintenance monitoring improve accuracy, as well as productivity.

Hydrogen oxygen acrylic flame polishing has been applied also to multi material composite and irregular 3D shapes. Lasser etching and engraving compatibility doubles product offerings.

As regulatory emphasis is on the need to lower workplace emissions, the development of clean flame technology is picking up, particularly in the emerging markets, which are in need of both sustainability and efficiency.

To any company aiming at producing perfect, glassy acrylic coating with the view of offering products of those types, the switching of acrylic flame polishing to an electrolytic water welder is a groundbreaking move. The implementation of oxygen hydrogen flame generator acrylic polishing system guarantees unmatched acrylic edge translucidity alongside massively minimized environmental impact through zero carbon emission polishing procedure. Professional flame polisher for acrylic simplifies the production process and maximizes efficiency as well as the elimination of operational risks inherent in the storage of gas cylinders, and is suitable to both small workshops and large-scale manufacturers.

Acrylic flame polishing gives the appearance of optical quality finishes in areas unattainable by traditional methods, such as smooth, glossy edges, and a reliable output over complicated shapes. The method of flame polishing acrylic surfaces is easily learnt among the operators to use in luxury displays, technical parts or architectural features. By implementing these advanced systems, the industry leaders do not only future-proof their processes but also establish a new standard about how to flame polish acrylic of quality and sustainability, winning a competitive advantage in the world market of high-quality acrylic finishing.