Adding a certain amount of Brown gas to the fuel burner for combustion assistance in hazardous waste incineration has outstanding emission reduction effects

With the tense international energy relations, South Korea and the Chinese Academy of Sciences have successively conducted catalytic combustion research on brown gas, combining three technologies of brown gas combustion, brown gas mixing fuel combustion, and brown gas solid waste catalytic combustion to achieve certain results in the application of medical waste incineration.

The principle of brown gas catalytic combustion

Hydrogen combustion is a typical chain reaction process, where when a molecule of water is formed, two new intermediate active substances H and OH are obtained.

O2+2H2→H2O+H+OH

The combustion rate of a mixture of CO and air is very low, and when there is hydrogen containing substances, the combustion rate will significantly increase.

Due to the continuous production of new H in the OH+CO → CO2+H reaction, it will continue to circulate once the reaction is started. Even if the supply of brown gas is stopped, the reaction will continue, and hydrogen participates in the reaction but ultimately returns to its original state. Due to the chain propulsion of hydrogen on the oxidation reaction of combustion intermediates, the oxidation reaction rate of CO, hydrocarbons etc is increased, which can significantly reduce the air excess coefficient while maintaining combustion performance, thereby reducing exhaust heat loss and improving the thermal efficiency of the combustion system.

| Model Number | TX-HO10000 |

| AC Voltage Requirement(V) | 380 |

| Phase | two |

| Power Consumption(kw/h) | 35 |

| Max. Gas Output(L/h) | 10000 |

| Max. Working Pressure(kg/cm2) | 2 |

| Max. Water Consumption(L/h) | 5.4 |

| Water Feed | automatic |

| Flame Modifier Feed | manual |

| Shell Material | iron plate spray |

| Water Requirement | purified water or distilled water |

| Cooling Method | air cooling |

| Dimensions-L*W*H (mm) | 1500*910*1900 |

| Gross Weight(kg) | 850 |

| Ventilation Space Requirement(mm) | 400mm in each direction |

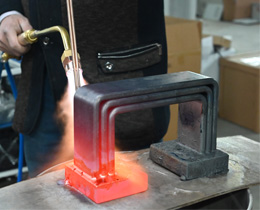

The application of Brown gas catalytic combustion technology in medical waste incineration has achieved good results after 6 months of use.

(1) Brown gas significantly accelerates the oxidation reaction rate of CO in a controlled gas incinerator, reduces the activation temperature of CO conversion to CO2 by about 150 ℃, and significantly improves the combustion efficiency of the incinerator.

(2) The ratio of the total amount of Brown gas added to the amount of flue gas in the incinerator, even if less than one thousandth, can significantly change the combustion state of the incinerator and reduce the level of flue gas emissions; At the same time, Brown gas has an adsorption effect on the furnace wall, and its hysteresis effect is significant.

(3) In the actual production process of medical waste incineration, the use of Brown catalytic combustion technology can reduce the total smoke emissions by about one-third.

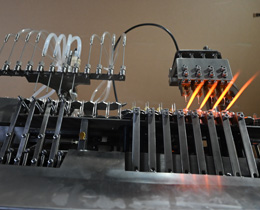

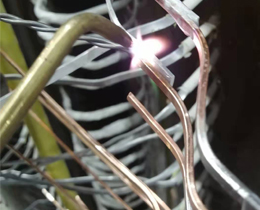

Oxyhydrogen generator quartz scientific glass vacuum sealing machine is mainly used for oxygen-free and water-free vacuum-sealed storage of samples. The whole setup system consists of oxyhydrogen generator, glass tube vacuum sealing machine, and vacuum pump.

Oxyhydrogen generator is quite safe since it does not require gas cylinders and no risks of leakage and explosion.

Oxyhydrogen generator consumes water and electricity,electrolyze water into H2 and O2,we can use H2 and O2 as source of flame replacing acetylene or natural gas or other fuel.