With the expertise knowledge of oxy-hydrogen production, there is a rare position to look deep into the fascinating realm of the Brown-gas and HHO. Let’s talk about what is a brown gas? In essence, the gas, which is produced by Brown, is completely a mixture of 2 hydrogen 1 oxygen molecules as is the case with the atoms contained in water. This oxy-hydrogen gas, commonly known as HHO or the Brown’s gas HHO has been intriguing the industrial fields and research circles because of its wide range of applications both in the field of welding as well as in clean energy. In this blog, you’ll find an overview of alkaline water electrolysis—the core process for producing Brown’s gas—and an introduction to featured products such as advanced brown’s gas machines and HHO brown’s gas generator. In the later parts of this blog, we will talk about brown’s gas benefits.

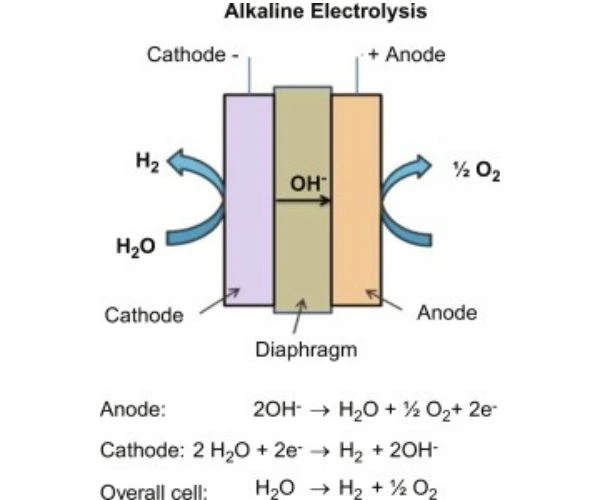

How to split water into hydrogen and oxygen? Water, simply stated, is a compound of two hydrogen elements and a single oxygen element which is written as H2O. Electrolysis is used to dissociate the molecules of water based on the reaction as 2H₂O → 2H₂ + O₂ (two hydrogen one oxygen). Under alkaline conditions, usually with the aid of potassium hydroxide (KOH) or sodium hydroxide (NaOH), the presence of such electrolytes decreases the overpotential and thus the energy requirements to carry out the splitting process become less intensive. The alkaline electrolysis water to hydrogen and oxygen is based on the delicate chemistry of this transformation, which allows obtaining the Brown gas. The analyses of the brown gas vs pure hydrogenn flames apply significant disparities: with the presence of oxygen, there are temperature peaks of flames and changes in their qualities of combustion, which makes the gas of Brown the most suitable tool in a variety of tasks.

In order to obtain the production of brown gas with the help of the alkaline electrolysis, it is necessary to create the solution of alkaline type, such as potassium hydroxide or sodium hydroxide. Install strong nickel electrodes into the electrolysis cell and a closed vessel that will contain and keep apart gases. With the introduction of direct current, and close supervision on the process, the hydrogen and oxygen gases are released, and they are collected in a separation cell for the best electrolyte for hho. The gas is then evaporated and an arrestor through a flame is added to assure an operation safety. This methodical procedure, characteristic of alkaline electrolysis of water, underpins the operation of reliable brown’s gas machines and HHO brown’s gas machine.

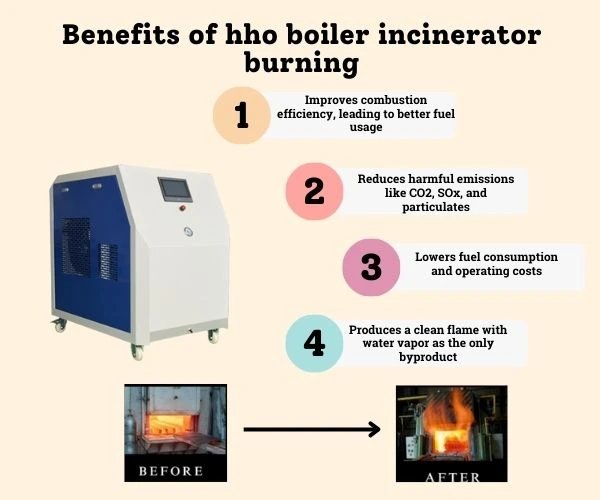

Modern brown’s gas generator for incinerator including those used in burning incinerators have high flow rates and sturdy safety attributes. Modular oxy-hydrogen generators combine several electrolysis cells with stringent current and voltage regulation measures and guarantee the best output and safety of operators. The decision on which construct type to use, that is, in the design of a membrane or a non-membrane electrolysis cell, is also a design factor that can be oriented to enhancing purity with membrane cells, or by being simple and having less maintenance requirements with non-membrane cells. This kind of equipment is critical to the development of the utility of brown gas HHO technologies.

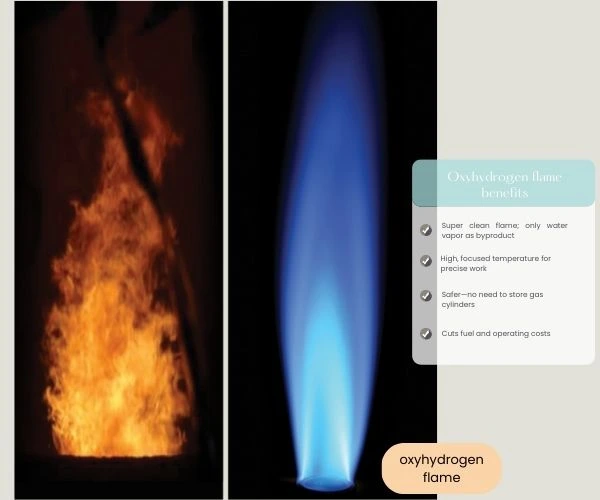

The assessment of gas production by Brown involves determining the rate per ampere and appreciation of the relationship between the current density and yield efficiency. The concentration of the electrolytes also has a great influence on the purification of gases affecting the quality of combustion and working efficiency. The HHO flame temperature, reaching between 2800°C to 3500°C, enables precise hho flame polishing and efficient cutting. Surprisingly, although the thermal energy density of the gas is lower than that of pure hydrogen, the gas offers application benefits specific to its 2 hydrogen 1 oxygen composition as advocated by Brown. Now we understand a bit about what is hho!

A powerful oxyhydrogen flame produced by the gas of Brown makes oxyhydrogen gas welding and cutting operations positively, in the sense of providing a clean, well heated, and controllable heat source. It provides good cleaning on the surface and removes rust and the less good polishing small fires used in precision manufacturing. Furthermore, the gas under consideration, the gas made by Brown, is used in the area of incineration and waste removal that meets the environmental benefits of that period: the burning of the gas forms water as a by-product and no carbon emissions, which is even more environmentally friendly in the context of emerging trends in the environmental agenda. With these features, the gas is an asset to the industries that are looking to achieve efficient and green solutions.

There should be no compromise where the application of the appropriate safety precautions is concerned when handling HHO flame arrestor. To prevent flame flashbacks and explosions, the flame arrestors and backflow preventers are needed. There is proper ventilation and leak detection, which further mitigates hazards. Electrical safety considerations such as insulation and circuit protection products are helpful to protect both operators and equipment- precautions that are essential in the management of HHO brown gas generators.

Low gas production in a brown’s gas machine is often due to improper electrolyte strength or degrading electrodes, while excessive heating can usually be resolved by adjusting current density and duty cycles. Fluctuations of flames are mostly due to a steeraged structure of gas-air mix or impure nozzles. Addressing these issues not only ensures reliable and efficient operation of any brown’s gas machine but also strengthens its safety profile—making full use of brown’s gas benefits in industrial settings.

When considering how does brown’s gas differ from hydrogen gas, the answer lies in composition and application. Brown’s gas, produced by alkaline water electrolysis, is a unique HHO blend containing both hydrogen and oxygen (typically a 2:1 mixture), whereas pure hydrogen gas contains only hydrogen molecules. Such a difference influences the temperature, combustibility, and the flexibility of the brown’s gas HHO to highly specialized uses.

Innovations in brown’s gas machines and alkaline water electrolysis are opening promising avenues for sustainable industrialization and eco-friendly energy. With a deeper knowledge of the underlying chemistry and the operation of these systems, users can unlock the true capacity and brown’s gas benefits of this 2 hydrogen 1 oxygen HHO mixture. With the rapid spread of interest in HHO and brown gas machine technology among researchers and industry, the adoption of such solutions leads to a cleaner and more sustainable energy taking the centre stage of modern development.