The need to decarbonize and use renewable energy in nations is increasing at a very high rate, and so is the demand of clean hydrogen. The practical experience in hydrogen gas production and hydrogen energy storage is becoming a necessity to the future engineers and scientists. Universities and research facilities are currently investing in integrated learning platforms systems, which are systems that integrate practical instruction on pem electrolysis, green hydrogen production and energy storage principles. The method bridges the gap between textbook knowledge and practical skills, and students are ready to begin careers developing the hydrogen economy with the skills of the pem electrolysis technology.

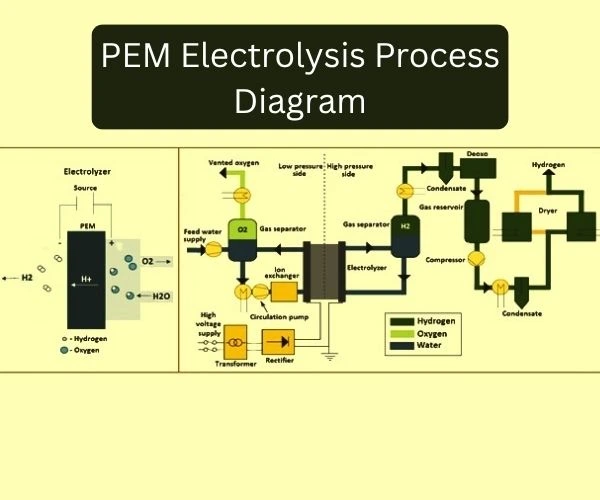

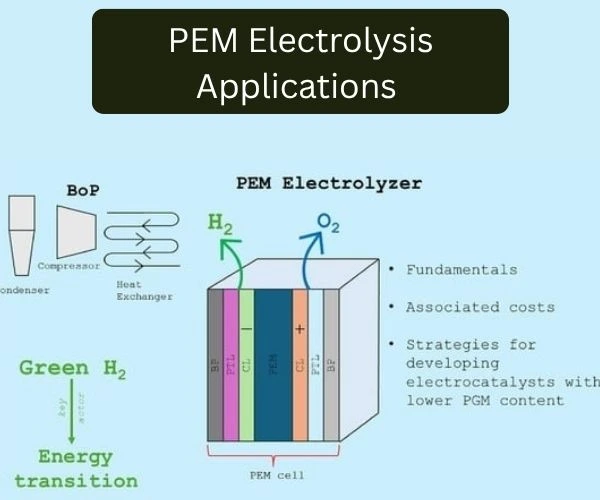

The core of these systems is the PEM electrolysis technology that is the most efficient and clean modern process of separating the molecules of water to obtain hydrogen. But how does pem electrolysis work? A PEM electrolysis cell can separate hydrogen and oxygen using a Proton Exchange Membrane and solely using pure water and electricity. PEM electrolysis is low temperature and can be rapidly started, unlike older alkaline cells, which have no chemical pollution risk, and produces high-purity hydrogen, thus making pem electrolysis for hydrogen production both in laboratories and in scale-ups.

A strong instructional system consists of a number of integrated components. First is the pure water circulation unit- it will have tanks, high precision pumps, high grade filters and the water quality sensors that ensure that only ultra-pure feed is supplied to the electrolyzer. The PEM electrolyzer unit is the next component, and a specific power supply designed to fit the changing conditions in the laboratory. The produced gas is then directed to a gas-liquid separation stage and special purification units after the electrolysis process which makes the operation of the process safe. Real-time data monitoring, commonly presented as a PEM electrolysis diagram and interactive touchscreen, is essential not only to teaching but also to research and this way all experiments become transparent and measurable. This forms the core of a genuine PEM electrolysis system in education and hydrogen production electrolysis research.

The benefit of being able to see all the steps in hydrogen gas production is one of the big advantages of these systems. Students will have a chance to see the influence of various current levels on the rate of hydrogen generation, observe the process of bubbles separation in transparent chambers, and then trace the purification process. A silica gel along with molecular sieve refines the gas stream, so that only dry and ultra-pure hydrogen reaches the output, which is important in fuel cell applications. Not only do these methods of hydrogen production methods bring to reality core principles but they also help in proving the essence of achieving the utmost levels of purity in hydrogen production through electrolysis.

In addition to production, safe storage of hydrogen is also a major concept in the laboratory. State of the art instructional systems also incorporate solid-state hydrogen energy storage tanks, which are systems that store hydrogen in metal alloys under low pressure, which is then released on-demand. This excludes the risks of high-pressure cylinders. Students are able to test the charging and discharging cycles, real-time storage capacity, and compare the safety features directly. These systems are the core of an Integrated PEM Electrolysis and Hydrogen storage Teaching System in which theory is transformed into reality.

The contemporary systems include the use of PLC (Programmable Logic Controller) automation and user-friendly touchscreen interfaces. They permit high accuracy in controlling the processes, diagnostics of the system, and complete data recording- making it possible to analyze the PEM electrolysis technology in detail under different conditions. The exact way theory is converted to practice is illustrated by real-time plots of hydrogen gas production as the input parameters vary. To the researchers, these platforms allow full automation of tests taking up to many hours, publication reproducibility, and easy integration of sensors for pem electrolysis for hydrogen production principles and applications.

The flexibility of an integrated system is a key value that it offers across the curriculum. Students of chemistry observe with their own eyes how hydrogen generators for labs are being used in labs. Energy engineers are experts who learn to integrate systems for green hydrogen production and power-to-gas applications. A hydrogen production electrolysis using renewable sources can be experimented directly in environmental science classes. In more advanced studies, students and faculty will have the ability to adjust the parameters to explore the degradation of catalysts, storage material, and effective integration with solar power or wind power.

Lab safety is paramount. These teaching systems are safe in nature since they use pure water electrolysis (no dangerous chemicals) and solid-state hydrogen storage, which is safe to use by students. There are inbuilt redundant pressure sensors, backflow prevention valves and audible/visual fault alarms. This makes any person operating the setup, whether on a demo or on intensive research, assured of learning due to the safety standards of the PEM electrolysis for hydrogen production and hydrogen production through electrolysis system as well as the dependability of the PEM electrolysis technology.

Real strategic advantages are achieved by investing in the Integrated PEM Electrolysis and Hydrogen Storage Teaching Systems. They improve the quality of education, and students develop the technical skills demanded in hydrogen energy storage, automation of the systems and integration of renewable energy. The departments with such systems have competitive advantages in receiving research grants and joint projects. Graduates come out prepared to work in industries that are at the forefront of the hydrogen revolution – pushing the development of hydrogen gas and its implementation.

PEM electrolysis, green hydrogen production and hydrogen energy storage are some of the tools that have become extremely important in the world as it rushes towards a low-carbon future. Integrated systems that are practical in nature overcome classroom and industry disparities and enable students to pursue careers that will involve innovation in hydrogen gas production and influence the renewable energy transformation. These platforms are not only the development of education- but the actual step towards sustainable education in science and technology.