The oxyhydrogen generator is the groundbreaking hydrogen fuel technology, which provides HHO gas, generated by the way of the innovation in the field of electrolysis. Hydrogen and oxygen molecules are combined to form the HHO gas which is able to send a strong clean-burning fuel of welding, cutting, and other industrial purposes. Learning the principles of how HHO generator functions is essential to the safe work and to use machinery with the maximum duration. The oxyhydrogen generator uses accuracy in its electronic regulation and effective electrolysis chambers to produce optimadry cell hho generator how it works allows the operators to know when there is a problem that might arise and as such, request the technology to fix that problem before it can become a matter of safety or performance compromising. This is a detailed manual that tells about key points of hho generator installation of how hho generator works, the working process, safety measures and maintenance in the 600 L/ h oxyhydrogen generators. The importance of safe use and inspection can never be overemphasized, poor handling of equipment exposes individuals to the dangers of damaged equipment, personal injuries, loss of operations when the equipment is used in critical work environments.

How hho generator works? The operations of hho generator may be studied considering the basic parts of this tool and their mutual relationships. The oxyhydrogen generator works based on the principle of electrolysis of water- electric current divides the H2O molecules into hydrogen gas and oxygen gas in closed electrolysis chambers. Why is stainless steel used in hho generators? The core of this process is made up of stainless steel plates; the reason as to why stainless steel is incorporated in hho generator is based on the fact that it has excellent corrosion resistance, the ability to conduct electricity and its ability to survive in continuous electrolysis and best electrolyte for hho generator among other things. Depending on the usage, the most effective electrolyte to use with hho generator is either potassium hydroxide (KOH), sodium hydroxide, or specialty KOH and NaOH electrolytes that have different merits in terms of gas yield, equipment longevity, and operating expenses.

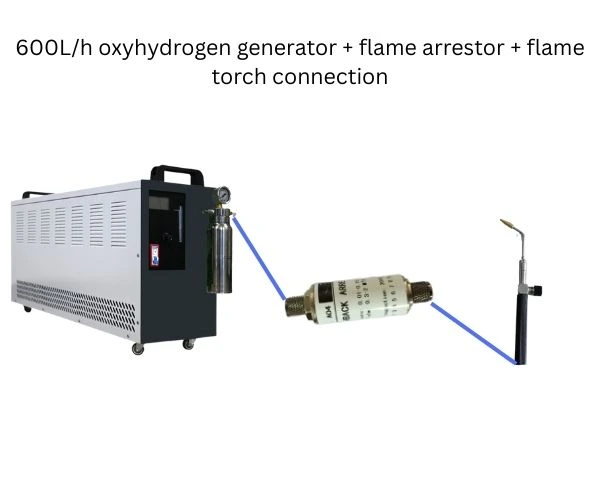

Hho torch is just the point of delivery where the HHO gas reacts with oxygen to generate extreme thermal energy to be used in welding and cutting. The character of the flame, mixture ratio of gases and the torch nozzle design directly influence the work quality and safety. The hho flashback arrestor is the safety device that is critical, in that it will stop any back-blast events where the flame is forced retrograde through the gas delivery lining into the generator. Flashback arrestor for hho gas has special check valves, temperature sensitive mechanism and flame arrestor media that immediately stops situations of reverse flow. Learning about the hho torch and flashback arrestor as safety systems, not as dissimilar parts, will make operators realize that they are interconnected to offer protective actions.

Through proper hho generator installation, the groundwork of the safe and efficient operation of the equipment is created and many possible issues are eliminated even prior to the introduction of the equipment.

Step 1: Set-up – Make the oxyhydrogen generator stationary on a stable and flat surface that does not have any splashing of water, extreme temperatures or direct sunlight. Necessary ventilation of the surrounding the unit to allow air to cool and the hydrogen/oxygen gas to be dissipated. Install the machine in a place where operators can have easy access to the display, pressure gauges and the maintenance ports without having to reach and bend.

Step 2: Attach Gas Tubing -Install a high-quality PTFE (Teflon) or specialty HHO gas tubing to the output of the generator with compression fittings or NPT connections that are compatible with your type of machine. Install tubes of routes out of picturesque edges, hot areas, and where they may be ruined or hooked in the conduction of usage. Make sure that all connections are hand tight as well as one-quarter turn, tighter can break fittings and less tightness can leak the gas.

Step 3: Installation -How to make hho flashback arrestor – Attach the flashback arrestor hho torch(immediately above the hho gas generator outlet and also before hho torch). Flashback arrestor hho torch connection should be placed in such way that operators can clearly see it when using the device and react severally in the event of development of backup conditions. Check the flow of the arrows on the arrestor to be sure that it is directed away (towards the torch) to be correctly installed.

Step 4: Fill Electrolyte -Fill the generator electrolyte reservoir with a highly recommendable electrolyte in hho generator as indicated in your equipment manual. Add distilled water combined with the recommended electrolytee concentrations i.e. 1:3 radio(25%-30% concentration) of the electrolyte to water depending on machine requirements and usage. Care should be taken not to use dirty water or non-certified best electrolyte for hho generator installation blends that impair the performance and destroy internal parts.

Step 5: Check Electrical Connection – Check to ensure that all power connections are made as per the specifications, required electrical cables are used which are of right size and circuit protection is provided. Do not use faulty power cords, loose connections or changed electrical settings.

How to check hho gas production? The use of a 600 L/h oxyhydrogen generator will involve the need to know the correct ways of starting the generator, how to test oxyhydrogen torch output, and performance behaviors. Turning the Machine on – Turn the power switch to the primary power source, the electrolysis function should then be used based on what your model of the generator will allow on control. The majority of the contemporary machines indicate the pressure outputs (usually 0-10 psi) or gas production speed (0-600 L/h) and the state of operation as digital. This is because to let the electrolysis chamber approach the ideal conditions of operation, provide a little test time of 30-60 seconds beyond which the torch gas valve ought to be opened.

Adjusting Gas Output – The majority of 600 L/h models have adjustable output control to enable the user to adjust gas output between minimum (20-30% output) and maximum capacity (600 L/h). You should also start with lower levels of production when commencing operations and then gradually increase to the demanded production rates as work requirements. High output rates boost thermal loading and electrolyte utilization-one must not maintain high output rate for a long period to avoid overheating of equipment and reduced maintenance periods.

Litigation of the HHO Torch – When the oxyhydrogen generator has been started and is running smoothly, which is indicated by the display of normal pressure in the readings, it is notable to begin the lighting of the hho torch gas valve by rotating the valve counter-clockwise by 0.5-1 full turns. Before the torch opening, place a source of ignition (lighter or piezo ignitor). The HHO gas sparks off forming a light blue flame that is unique in its oxygen and hydrogen gas mixture rich properties. Turn on/off the intensity of the flame through a control panel on the generator to obtain desired characteristics and intensity of the flame.

Normal Operating Pressure and Output: A properly functioning 600 L/h unit will also have an output pressure of between 0.8Mpa- 1Mpa when operating at normal condition with the delivery rates depending on the selected unit output setting. Production of gas ought to experience non-pulsing, non-spattering and non-drastic changes in pressure. The nature of the flame must be steady and have a pale blue color as they represent correct proportions of hydrogen and oxygen mixtures and effective combustion.

The necessity of how to make hho flashback arrestor is only known in consideration of the flashback events, their causes, and preventions. An exceptionally hazardous situation is reached when flame moves inverted in the gas delivery circuits and to the generator, a flashback can also result in equipment damage, electrolyte ignition, and personal harm. The hho flashback arrestor averts this disastrous situation with inbuilt check valves and flame arrestor media, which closes reverse-flow circumstances instantaneously.

How to detect oxyhydrogen gas leak? Typical Flashback Reasons – Water condensation within the delivery tubing forms moisture blockages that limit the flow of gasses and lead to alterations in pressure which result in an occurrence of backflash. High pressure of torches overburdens the gas delivery channels whereas a momentary vacuum in case of sudden closure of the torch valve attracts flame towards a backward direction. Ambient air infiltration and combustion dynamics with where backflash is preferred, occur due to the low generator output pressure in comparison with atmospheric conditions. The maladjusted size of nozzle and flame characteristics, broken pieces of the torch or the wrong gas mix ratio destabilizes flame properties and risks flashback.

Prevention Strategies- The flashback arrestor for hho gas is the main protection method yet integrative practices by the operators are required. Adequacy, hho flashback arrestor hho torch knowledge Ensure-how to use hho flashback arrestors: temperature sensitive arrestors as well as special ceramic media that block the flame physically will work. Be sure of adequate generator pressure (0.8Mpa to 1.0Mpa) to exclude infiltration of atmospheric air. Install moisture traps in gas lines where daily drainage practices are to be carried out to debride up of the condensation pits. How hho generator works? Shut down the hho torch valve gradually and smoothly and not abruptly. Check the pressure of generators in operation and stop working in case of any unexplained decrease in pressure, which is an indication of an issue in the delivery system. The proper way to close a torch involves the following steps; (1) reducing the generator output to a minimum value, (2) closing the torch valve as fast as possible, (3) switching away the power switch, (4) letting the rest of the HHO gas into the machine evaporate, and (5) examining the machine area to see no flame before walking out.

Proactive maintenance will increase the lifespan of equipment as well as preventive contact with manufacturers will fix problems before they grow big. Torch Nozzle Cleaning – It is desirable to leave the hho torch to cool naturally (5-10 minutes) after each work session, and then clean the hho torch nozzle opening by a soft brass brush cleaning away any debris, soot or mineral deposits. Carbon steel brushes and rather hard tools should never be used as they destroy the nozzle aperture. In the case of stubborn deposits, moist the torch nozzle with water after 30 minutes of soaking and then brush.

Dampter Maintenance – The dampter (moisture trap) holds the water condensation in gas delivery lines and has to be drained every day. Turn off the dampter drain valve emptying all the water, and then reopen the selected value to continue the collection of moisture. Contaminated or plugged dampers limit the passage of gases to the back and add to the risk of backflush risk- change the dampter element after 3-6 months of operating, based on the working hours and the level of environmental humidity.

Electrolyte Replacement Schedule – Replace electrolyte after 3-6 months of regular usage (40 or more hours of operating monthly), or 6-12 months of light usage (less than 20 hours of operating monthly). Pour out the remaining contents of the electrolyte using the reservoir drain port into suitable waste containers, rinse the inside chamber using tap water 2-3 times, add fresh distilled water or purified water and electrolyte concentrate in required proportions.

When to Contact Hho Generator manufacture – To contact manufacturers because of: (1) drop in performance and more than 15-20% even with recent electrolyte replacement, (2) repeated pressure changes or erratic readings, (3) continued leakage of gases not because of tight connections, (4) electrical faults or difficulties with displays, (5) any safety issues including unusual fumes, sparks or temperature. The hho generator installation firms have technical support call centres, offer comprehensive instructions on troubleshooting and offer authentic spare parts that will keep them in safe use.

China HHO Oxyhydrogen Generator Factories and Sourcing – There are numerous sourcing units of 650l h oxyhydrogen generator for glass in the china hho oxyhydrogen generator factories, which provide direct supply at favorable prices. In sourcing overseas manufacturers, ensure it has the certification, warranty and access to technical support. Established factories have after sales services such as provision of spare parts, technical manual and troubleshooting. Estimate maintenance and consumables (electrolyte, torch nozzles, dampter elements) cost in the first year of operation of about 15-25% of equipment cost.

Applications and Pricing of Glass Work – The 650l h oxyhydrogen generator in glass applications is a niche product that features high-temperature, clean-burning HHO as an excellent choice to cut, heat and weld glass, seal it and also in a variety of artistic operations. Oxyhydrogen water generator price is dependent on the size of production capacity, quality of assembly, and accessories included- 600 L/h units normally cost between 800-2500 dollars depending on manufacturing company and market economy. Glass-specific designs can have custom styles of torch and extra safety can be added and it would fetch 20-40 percent higher than normal welding/ cutting units.

Oxyhydrogen generator troubleshooting Resources – Problems can be addressed by consulting oxyhydrogen generator troubleshooting information supplied with equipment manuals, by calling manufacturer technical support, or using communities on the Internet that focus on oxyhydrogen technology. Record symptoms that are peculiar to the document (the pressure level, output rates, any specifics of flames, the appearance of errors) prior to reaching out to support- any detailed information speeds up the diagnosis and fixing.