The electrolyte is the key ingredient to the operation of HHO generators since it is more than merely an inert chemical solution. Its behavioral characteristics directly influence the rates of hydrogen production, the lifespan of the electrode, safety of the operation or the system reliability. Known as the conductive medium, the electrolyte facilitates the electrolysis of water; the breaking down of H2O molecules into hydrogen and oxygen gases by the application of electrical energy.

Systems of professional grade require accurate electrolyte specifications in terms of decades-long engineering optimization. It is the chemical properties that determine how successful a best electrolyte for hho generator will be as a precision instrument or will cause a cascade of deterioration due to premature electrode wear and contamination: chemical properties, such as conductivity (determining ion movement) and pH buffering (retaining an alkaline maintenance), corrosion resistance (protecting metallic parts), and thermal stability (resistance to extreme temperature changes) all play a role in whether the HHO generator will work well or fail due to sudden deterioration of the electrode and a chain reaction in its contamination.

Alkaline electrolyzer efficiency science is the point of difference between amateur experimentation of HHO electrolyte concentration systems and professional grade HHO systems. Poorly developed solutions result in much less gas production even with the same amount of electricity over the same time; impure electrolytes corrode the electrodes in only a few weeks; small conductivity areas reduce the efficiency of gas production; poor thermal control hastens chemical corrosion. Professional manufactures such as those at Ptxsons spend a lot of money on research in the area of electrolytes since it provides one of the biggest performance against the DIY systems.

Which is best for oxygen hydrogen water welder hho gas flame generator? There are two chemical alternatives prevailing in professional HHO applications: Potassium Hydroxide (KOH) and Sodium Hydroxide (NaOH) both of which are alkaline compounds and allow an individual to make an efficient water electrolysis generating ionic reactions via electrolysis.

Potassium Hydroxide (KOH) is a superior option of professional systems. High conductivity (215 mS/cm baseline) means that ions flow faster, so more gas is produced by any amount of electric input. KOH has an outstanding pH stability- it shows target alkalinity over long periods of operations despite the progressive loss of hydroxide ions by electrode reactions. Corrosion at minimal electrode levels maintains the integrity of the stainless steel surface; the electrodes are also opaque and useful with 6-12 month periods of operation. The commercial uses would be priced higher since the rates of gas production (7-15% higher output as compared to NaOH equivalents) require higher prices.

HHO electrolyte formula can be regarded as a high benefit and trade off alternative. Reduced starting price (including 800-1200/kg (compared to KOH 1500-2000/kg)) is budget friendly. The functional operation capability with lower performance indicates adequate conductivity (207 mS/cm). They are easier to handle (a little less caustic) and this minimizes workers safety overhead. Nevertheless, serious drawbacks become evident: increased crystal growth at storage (more frequent agitation is needed), much higher corrosion of electrodes (15-25 shorter life than at KOH), and overall poorer pH buffering (electrolyte has to be replenished more often).

The application calculus to place reliance on comparative selection KOH recommends premium continuous-duty professional generators with electrode replacement costs and downtime significantly exceeding chemical price differentiation; NaOH is recommended in intermittent hobbyist use where the primary factor is the minimum cost of the material used.

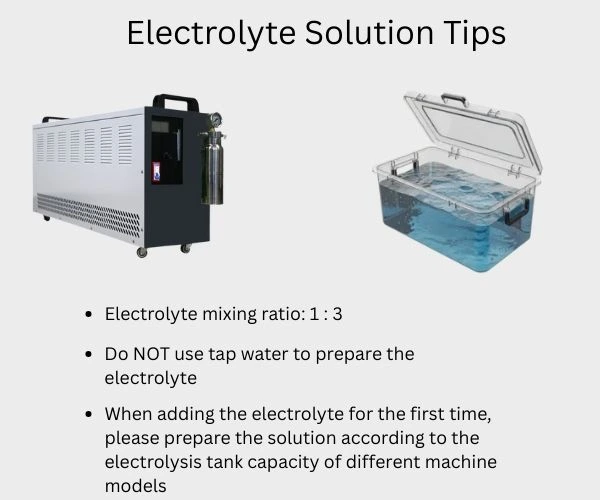

How to make electrolyte water for hho? Accurate concentration ratios are used to give conductivity goals that are necessary in alkaline electrolyzer efficiency. The standard ratio in the industry is 3:1 (hho electrolyte ratio)of water to chemical ratio that attains 25-30 percent concentration:

More sophisticated applications that aim to achieve the greatest gas production utilise greater concentrations: 1.5-2.0 percent (compared to mass of water) solutions with conductivity of 230- 240 mS/ cm. This high-performance formulation is sensitive to thermal control as the higher concentrations will produce a higher amount of heat during the electrolysis process.

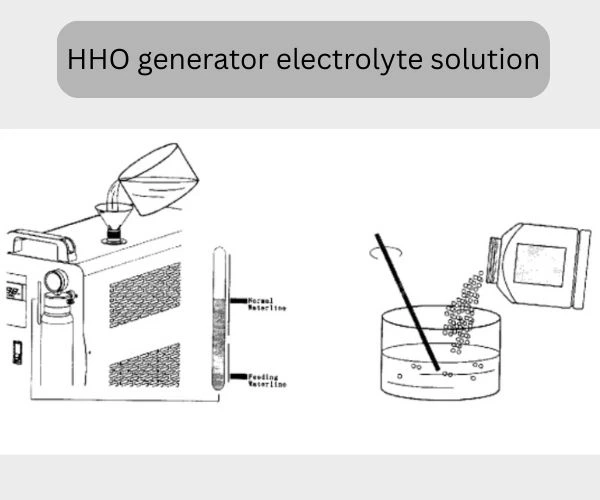

Precise instructions To prepare Electrolyte Water to use in HHO are required:

Critical Procedure: Since dissolved minerals will drastically lower conductivity and increase corrosion rate, then do not use tap water. Exothermic reactions heat generated by caustic decomposition is avoided by temperature control during preparation. Specific gravity testing is used to ensure the accuracy of the concentration of the solution; deviation means that there is a measuring error that needs to be recalculated.

The professional high efficiency HHO electrolyzer systems require strict activity of conductivity checks with 0-2000 mS/cm accuracy meters. New KOH baseline measurements set the reference to 210-220 mS/cm; the values are falling, so there is a need to check the contamination or chemical degradation.

Monthly HHO Electrolyte Testing Protocols establish the trends in the performance:

Independent hho electrolyte concentration check: Newly pre-empted via hydrometer: Specific Gravity Assessment.

pH stability: pH is stable, alkaline.

Temperature Coefficient Compensation: Change in conductivity is 2 percent /1 o C. Any possible seasonal/operational variations in temperature caused by variations in measurement are normalised to the standard temperature of 25 °C with the professional systems and therefore facilitate accurate trending.

Although stainless steel electrode resistance is present, several degradation mechanisms induce as time on operations progress:

Electrode Corrosion Byproducts: This is the reason why even a small amount of corrosion causes the separation of metallic compounds to solution; as it gets higher, the hho electrolyte concentration of the impurities in the solution increases and impairs performance.

Mineral Contamination: Non-distilled water has dissolved minerals that attach to electrodes forming scale which decreases the conductivity and efficiency of heat transfer.

Thermal Degradation: Prolonged use of temperatures exceeding 80°C increases the rate of hydroxide dissolution and water loss which takes all solution sickly out of the target specification.

Replacement Indicators (replacement consideration caused by any of the single metrics):

The Replacement Frequency is dependent on operation temperature:

By tracking maintenance, we are able to predictively replace them, that is, well before performance drops to an irreversible point.

There are strict safety measures required in KOH and NaOH caustic properties. Chemical burns are very harmful to the tissue; it can destroy a person’s vision forever when exposed to it through the eyes. The PPE needed is chemical-resistant gloves, eye protective gloves that have ANSI rating, and protective apron.

Storage Requirements: Place in enclosed containers (never use metal) in a cool and dry area separated with acids and reactive metals. Violent reactions occur when contact with water-reactive metals (calcium carbide, etc.) takes place.

Are HHO Generators Safe? Adequately engineered systems with a good choice of electrolyte have good safety records. Safety systems that are fitted in integrally designed systems are flashback arrestors (flame backflash cannot enter the generator), pressure relief components (having more than normal pressure) and temperature regulation, which aims at stopping thermal runaway. The wickedness of the electrolyte formulation, contamination which leads to micro short circuiting mechanism, lack of cooling that enables thermal runaway and negligence in safety measures are hazardous.

Environmental Disposal: Spent electrolyte. The spent electrolyte must be neutralized by means of a dilute acid solution (5:1 water-vinegar mixture) and then it should be disposed. Professional-grade systems Ptxson have extensive safety facilities. Local regulatory assurance of chemical waste disposal is crucial, dozens of jurisdictions have requirement of waste disposal of hazardous waste at a disposal facility and not at a domestic sewage system.

Electrolyte solution becomes the core of all HHO generators and it directly influences the efficiency of the gas production, operating life and reliability of the equipment. Professional installations and amateur failures are separated by proper handling of electrolytes whether it is powering a oxygen hydrogen water welder or automotive fuel enhancing system. Following are valuable points which will guarantee high performance in the first place.

The most important thing is the mixing ratio: A ratio of 1:3 (electrolyte to water) should be saved (according to the size of your tank of electrolysis). Such balance maximizes the conductivity and excludes electrode overload. Excessive concentration accelerates the process of corrosion; insufficient dose suffocates the provision of gases.

There is no compromise of water quality. Do not use tap water contains chloride ions which violently attack stainless steel pipelines, tanks, and electrodes resulting in early failure in several months. Only distilled or purified water (conductivity less than 5 -1) is guaranteed to be long-lasting. The investment will save thousands of money on replacement.