Copper tubing is absolutely essential to the safety and energy efficiency of the HVAC system, both in the installation of a new system and in repair. All technicians understand how to weld copper tubing directly influences not only the refrigerant retention but the performance and reliability in the long-term.

The current environment has never been more diverse: there are teams that continue using the time-tested techniques of traditional oxy-acetylene brazing, and those who have adopted the more environmentally conscious and futuristic oxyhydrogen welding as a way of achieving better outcomes. With the debate over oxyhydrogen vs oxy-acetylene heating up due to the need to lower emissions and gain more control, it is only natural that the question of how to braze copper hvac components becomes more and more about using the newest tools of the trade, such as the hho hydrogen generator and the latest copper brazing machine technologies to achieve the desired precision, speed, and peace of mind.

The difference between brazing and soldering is essentially one of temperature: soldering involves a filler metal that melts at temperatures below 840 o C, whereas brazing involves a filler that must melt at temperatures higher than this. In the case of modern HVAC installation, it is important to know how to brazing copper tube and perform correct copper tube welding.

The elevated heat of brazing provides the joints with high ability to endure the stressful pressure variations and regular thermal cycling. With a copper tube brazing machine, the accurate heat pulls the molten filler to all the joints through capillary action creating a seal that lasts years of service. Accuracy is important–even a fraction of an inch, unseen with the naked eye, can be a point of leakage or corrosion whenever temperatures change or there is moisture.

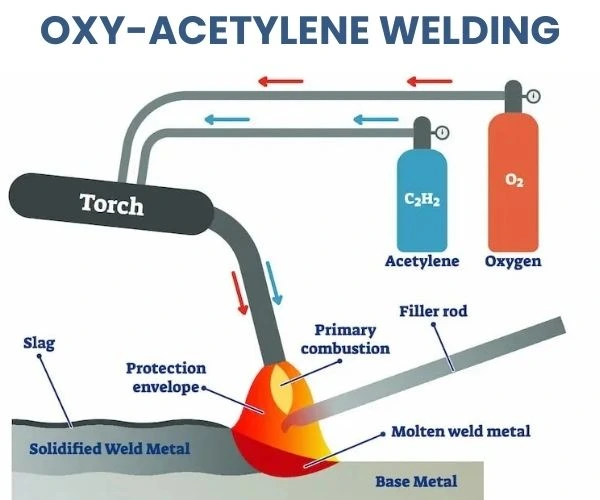

Conventional copper pipe welding of HVAC is based on the time-tested combination of oxygen and acetylene cylinders, which are joined to regulators, hoses, and torches- a system that any technician can master at the beginning of his or her career. To learn how to weld copper pipe, or to learn how to weld copper to copper, you need to know how to control the flame: the optimal neutral flame is the one used in copper pipe welding, but in special fittings or repair work a slight shift towards oxidizing or carburizing can be used. A correctly operated torch can guarantee that the filler metal pours through the joint at temperatures up to 6,300 o F, which is necessary to provide strong connections that are leak-free. The art and craft of how to weld copper tubing are both art and skill, as the work with pressurized cylinders, backfires, and carbon emission monitoring are all aspects of each copper job in HVAC.

Enter the future of copper joining with oxyhydrogen welding: no longer does a volatile gas need to be stored, but rather a hho hydrogen generator today creates fuel on demand through electrolysis of water, providing a pure hydrogen-oxygen blend to a hho welding torch or hho torch to provide unparalleled control and safety. Plumbers and HVAC professionals can now rely on a carbon-free fire with upgraded technology such as the TX-HO2000 hho generator welder that produces 2,000 L/h using only 7 kWh of power, allowing them to make precision welds with much less risk. This transition to oxyhydrogen welding is all about flexibility–there is less fume in the air, no large cylinders to trip over, and the torch is ideal in the field to do small repair work as well as in the shop to do high volume work.

The oxyhydrogen vs oxy acetylene welding debate is mainly based on two factors; flame temperature and precision. Oxy-acetylene burns up to approximately 6,300 0 F producing an extensive, intense heat profile that works well on larger joints but may occasionally result in undesirable overheating of smaller copper pipes. The oxyhydrogen flame temperature, which is usually around 5,072 o C, is equally useful in melting copper but provides a much more focused, pinpoint core. That focused energy can be used to achieve shorter welding times and much smaller heat-affected zone (HAZ). To technicians who need to know how to weld copper tubing or want to install it in a way that is more clean and safe, the benefit of oxyhydrogen over oxy-acetylene is obvious: less stray heat results in neater joints, lower risk to the surrounding insulation, and a much lower probability of collateral damage to the HVAC components, not to mention the subtle benefits of oxyhydrogen over oxy-acetylene techniques.

The TX-HO2000 heavy-duty oxy-hydrogen welder reinvents copper tube welding on the factory floor and the jobsite. It is designed to be versatile- automatic water feed, highly adjustable flame, and powerful 2,000 L/h gas output, it works just as well in welding large-diameter copper tube, welding copper wire, and welding copper pipe every day. With the advent of such innovations as the hho oxyhydrogen generator for welding, even small units can now easily fit into HVAC shops, without the clutter and hazard of compressed gas cylinders. Combined, these next generation machines enable HVAC professionals to connect more safely, cleaner, and faster, and increase the bar of copper tubing work.

The best copper joints are not only those that require high heat, but also those that require controlled overlap, accuracy in capillary fill and reliability even when the system is subjected to high pressure. To the people who really know how to weld copper tubing, it is obvious that success lies in a combination of art and science. Oxyhydrogen welding is more precise with a smaller heat-affected zone (HAZ) and improves the microstructure to maintain the mechanical strength of all connections. The choice of filler metals is important as well: BCuP alloys are generally the best choice when it comes to how to weld copper to copper, providing the reliability of simple joints, whereas BAg alloys provide the necessary flexibility to complex or dissimilar metal welding. In the current modern HVAC and plumbing systems, experts understand that the quality of joints is the benchmark- and with the accuracy of oxyhydrogen welding, performance and safety are taken to a new level.

Technique and safety cannot be divided during the process of learning how to braze copper HVAC tubing, particularly when using different methods of welding. Oxy-acetylene systems are in themselves dangerous, as they involve the transportation of high-pressure cylinders, as well as the possibility of torch backfiring and even exposure to carbon monoxide, so strict training and regular ventilation of the working area are indispensable. Comparatively, oxyhydrogen systems that operate off an HHO torch offer a very clear advantage: since no stored fuel gases are involved, there is no possibility of leakage or explosions, and the only byproduct is water vapor. Despite these safety benefits, professionals must always wear proper PPE and work within the confines of AWS/OSHA standards, but HHO torch technology certainly provides an additional level of safety that few others can offer to modern copper brazing work.

The bottom line is more than ever to the contractors. Although the initial investment in a standard cylinder-based copper brazing machine can be quite significant, the conversion to an HHO generator welder results in a continued saving- as all that is required is electricity and water to produce the fuel, not expensive gas fills. The methodology leads to a reduction in the number of consumables, waste, and a reduction in the time of the weld, providing a strong ROI to the shops that require high volumes or continuous brazing of copper. The efficiencies might not be very large initially, but when each copper brazing machine operation is multiplied by a large business the benefits of an HHO generator welder accumulate quickly.

The decision between oxyhydrogen vs oxy-acetylene is a matter of personal preference based on the specific requirements of your project: do you value the size of your shop, the ability to work on-site or the impact of your business on the environment. To the majority of technicians, installing an oxyhydrogen generator, dialing in an exact flame, and adhering to systematic how to weld copper tubing guidelines are the key to the best HVAC joints. With oxyhydrogen welding becoming more popular, practitioners are starting to consider the benefits of oxyhydrogen over oxy-acetylene in terms of safety, efficiency, and environmental concerns, which are equally important as learning how to weld copper pipe in the first place. In order to be ahead, consider the next-generation solutions such as the TX-HO2000 and other small-sized HHO generators at Ptxson , the portal to the new standard in copper HVAC brazing.