Oxyhydrogen torches powered by oxy hydrogen generators or brown gas generators are changing the way of industrial high-precision tasks. Oxhydrogen generator for welding and sealing become popular in metalworking and glassblowing because of a clean, high-temperature oxyhydrogen flame for precision work without the harmful byproducts of traditional fuels. Whether you’re creating intricate metal patterns or shaping glass in your studio or lab, the versatility of oxyhydrogen flame torches is unmatched.

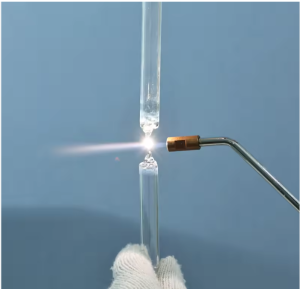

The core of an oxyhydrogen torch is the flame produced by a mixture of hydrogen and oxygen gases. The hho gas is produced on demand using an oxy hydrogen generator also called brown gas generator. Once ignited, the hydrogen burns cleanly in the presence of oxygen, producing oxyhydrogen flame that reaches temperatures of up to 2800°C.

What sets this torch apart is not just its intensity, but the fact that it leaves behind only water vapor as a byproduct. This results in a safer, cleaner, and more environmentally friendly working environment.

The ability to control flame size and heat output with great accuracy makes oxyhydrogen torches ideal for tasks where precision is critical. Unlike propane or acetylene torches, which release carbon-based residues, the oxyhydrogen flame stays clean and focused, allowing for greater detail and consistency.

What makes the flame torch special is not only its strength, but also the fact that it leaves only water vapor as a byproduct. This makes for a safer, cleaner, and more environmentally friendly working environment.

The ability to precisely control flame size and heat output makes oxyhydrogen torches ideal for high precision welding and sealing work. Unlike propane or acetylene torches, which release carbon-based residues, the oxyhydrogen flame is clean and concentrated, enabling a finer brazing process.

In nonferrous metalworking, the oxyhydrogen welding is a valuable tool for craftsmen and technicians who need finely controlled heat. It is often used to weld thin metals such as silver, gold, and copper materials. The precise flame makes it easier to achieve clean joints without overheating surrounding materials, which is especially important in tasks of jewelry making or micro soldering for electronics.

Welding and brazing also benefit from the torch’s high temperature and clean flame. There is less oxidation, which means a stronger bond and a more refined surface. In addition to fabrication, metalworkers often use torches for surface treatments such as acrylic flame polishing to give a smoother, more professional look.

Glassblowers rely heavily on the oxyhydrogen torch for both functional and artistic work. One of its most valuable applications is sealing and joining glass tubing, especially when producing laboratory equipment, where clarity and structural integrity are critical. Because the flame is so precise and pure, it does not introduce impurities or cause cloudiness, which is essential for scientific applications.

When working with heat-resistant glasses of borosilicate or quartz, a constant, high-temperature flame is essential. The hydrogen torches for glassblowing allow artists and technicians to shape these tough materials with ease. In creative glass blowing or flameworking, it is able to shape delicate and intricate designs from sculptures to custom ornaments without distorting the glass or leaving residue.

Oxyhydrogen torches have a number of significant advantages compared to traditional gas torches such as oxy acetylene or propane. The most significant advantage is zero carbon emissions. Since the only byproduct of combustion is water vapor, there is no risk of soot contamination or toxic fumes. This makes the workplace a cleaner and safer environment.

Another main advantage is the high temperature flame, which allows for faster heating and high efficiency when working with non-ferrous metals or quartz glass. Because oxyhydrogen generators produce gas on demand, there is no need for gas cylinders, which greatly improves safety. Precise flame control also gives operators greater flexibility when working with delicate tasks, reducing material waste and improving the final result.

The oxyhydrogen torch is used in a wide range of industries nowadays. Jewelers rely on them for fine welding and metal shaping. In the dental and medical fields, they are used to create high-precision surgical instruments and dental trays. Scientific laboratories appreciate their excellence in sealing and shaping glassware or glass tubes. The electronics industry values their ability to weld tiny components without damaging sensitive parts.

Artists and craftsmen also favor oxyhydrogen glassblowing torches to create crisp lines and sharp details on glass and metalwork. The hydrogen welding machine has a wide range of uses, making it a reliable gas generation equipment for both large-scale production and small-scale crafts.

Although oxyhydrogen generators are considered safer than traditional fuel gas systems, it is still important to follow safety guidelines. The use of flashback arrestors, proper ventilation, and pressure control systems are essential to preventing accidents. Such gas generation equipment are designed with safety systems to produce hydrogen and oxygen on demand using brown gas generators, which eliminates the need for gas storage and significantly reduces risk.

These oxyhydrogen torches provide one of the safest high temperature flame solutions and minimize environmental and operational hazards if you follow the manufacturer’s operating instructions or on-site training.

The oxyhydrogen torch works excellently in performance on a wide range of nonferrous and glass materials. It is particularly useful for gold, titanium, copper, silver, and other softer metals that require precise heating without oxidation. These materials weld well to a clean, controlled flame, which makes them ideal for applications such as jewelry making, precision welding, and fine metalworking.

While the oxyhydrogen flame delivers high temperatures, it is not suitable for brazing or welding stainless steel because the flame lacks the heat concentration and metallurgical compatibility. For glass sealing, the hho gas generator seals well on borosilicate glass and quartz glass, which are commonly used in laboratories and art studios for their strength and clarity.

With a focus on materials that benefit from a clean burn and high-precision flame, the hho brown’s gas generator provides a reliable solution for professionals who seek high-quality results without compromising safety or cleanliness.

While traditional torches still have a place in industrial areas, the oxyhydrogen torch offers a cleaner, more modern alternative. It has comparable temperatures to the oxyacetylene flame, but there are no toxic carbon emissions. It has a reasonable installation cost, and becomes more economical over time due to reduced fuel costs and maintenance requirements. Unlike propane torches that lack flame accuracy, the oxyhydrogen torch is able to provide precise positioning for intricate jobs.

As the industry continues to grow, so does the need for cleaner, safer, and more precise tools and equipment. Oxyhydrogen welding and sealing torches—powered by either a brown gas generator have proven to be highly effective in both metalworking and glassblowing. From crafting fine jewelry and scientific instruments to creating exquisite glass art, the applications are wide-ranging and far-reaching. With zero carbon emissions, high flame accuracy, and smart safety features, oxyhydrogen flame torch machines are quickly becoming an essential tools and equipment for professionals and craftsmen.